HDPE

• H.D.P.E lining membrane lends itself to an excellent lining system for a wide variety of applications in the area of water storage and conveyance. The combination of physical properties, large rolls without prefabrication, ease of high welding quality, and availability in large thickness are among the design considerations for selecting HDPE membrane liners. In addition, its complete inertness makes it safe to carry drinking (Potable) water. HDPE is free of plasticizers , fillers, lubricants or any other toxic or tainting substances that could leak out during its lifetime. HDPE liners were tested by the metropolitan water board (UK) and the NSF (USA) and was found safe for storing drinking water. HDPE has close molecular structure , thereby resisting the adhesion of algae and similar growths; snails or limpets may be scraped from the installed lining without risk of puncture .

• H.D.P.E membrane lining for water reservoirs may take a number of different forms • A complete impermeable lining of embankment and base without cover. • A complete lining with cover of earth or gravel for reinstatement offish or plant life . • Embankment lining to prevent erosion by wave action and rapid water level changes . • An intermediate layer between soil binding and structural concrete to safeguard future cracking of the concrete

• H.D.P.E applications for water storage and conveyance include :

» Lining of water conservation reservoirs .

» Lining of irrigation canals. Sealing of earth and rock fill dams and dikes .

» Lining of potable and raw water reservoirs for water supply waste .

» Lining of rain harvest reservoirs

» Lining of balancing reservoirs for irrigation .

» Lining offish ponds .

» HDPE lining has offered great opportunities for the economic use of earth reservoirs. Earth reservoirs constructed either by excavation in the natural ground or enclosing a site with embankments have always been the choice of engineers for cost-effective storage facilities . However, this practice was restrained by the availability of sites with impermeable soils. Alternatively, various types of less effective lining were used to control seepage from the storage facility. HDPE is widely used as the optimal lining system for water conservation reservoirs

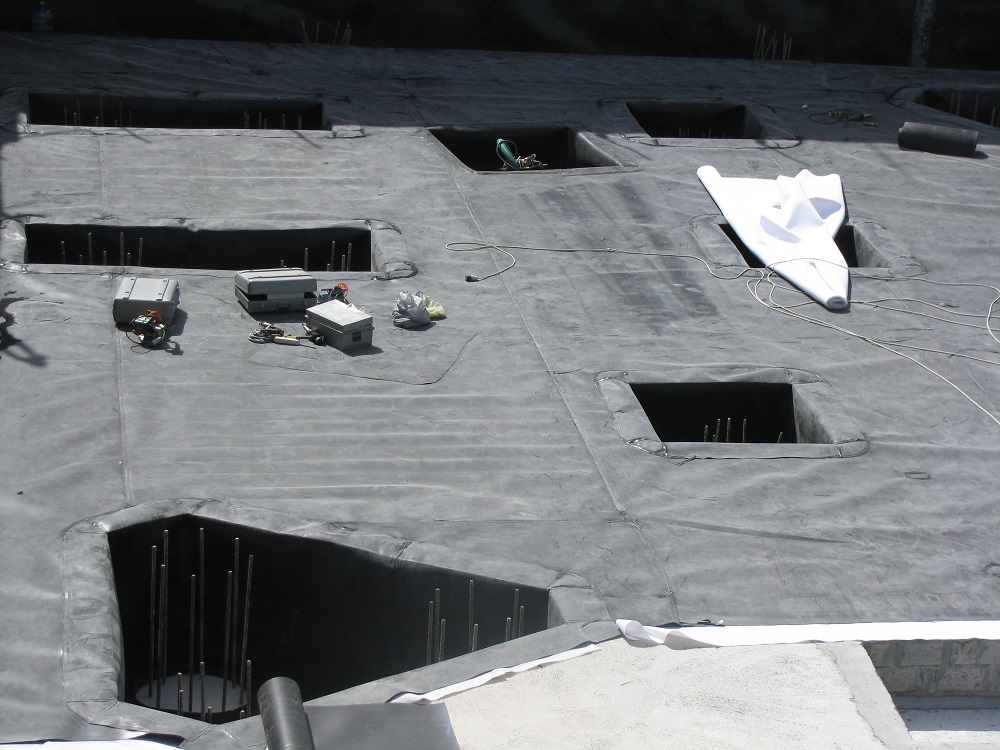

Structural Sealing

Insulation and sealing for concrete structures is considered as one of the main elements for the success of these projects and prolonging their shelf life. A lot of harm effects can occur to these projects due to the direct contact between the water and the construction elements such as concrete can lead to a lot of corrosion in the steel bars and damage to the main body of the building which definitely will reduce its shelf life. The collection of the underground water in the basements of such buildings will lead to a lot of environmental problems. A lot of works had been carried out to study the best solutions for insulating and sealing the concrete structures. The results of these studies showed that the use of Geomembrane sheets such as HDPE or PVC will solve the problem. The reasons of choosing these types of materials for different applications and in different places in the world are:

1. The excellent physical, mechanical and chemical properties for the durable insulation sheets which make these sheets able to protect any structure for a very long period. The reasons for this are:

» Their high resistance to all the chemicals which can attack it from the soil, from the underground water or from the sewage.

» Their high resistance to the stresses which are applied to the sheets during the installation or after the completion of the building. These stresses are such as:

→ The appearance of the capillary cracks in the concrete skeleton after sometime leads to the damage of the traditional insulating sheets if these sheets can not resist the elongation stresses, unlike the HDPE sheets which have tensile stress elongation of a value rates between 250% and 700%. This property makes the sheets able to cover any capillary cracks and though the water can not pass through them.

→ Any settlement which could happen to the structure creates a high tensile stress on the insulation sheets especially at the horizontal and the longitudinal welding joints. The HDPE sheets can resist these stresses successfully.

» Their high to the weather conditions specially the temperature up to 80 °C and the UV rays.

2. The Geomembrane sheets have a very high Durability Property. They can keep all of their physical, chemical, and mechanical properties for a long time without any changes even under any of the previous stresses. Some of the other insulation sheets have good technical properties but they are not durable like the geomembranes. So it is very important to choose always a durable insulation material.

3. The Geo-membrane sheets are easy for testing during their production and during the installation by using the most advanced electronic testing equipment at site. The tests are carried out according to the following procedure:

– Testing the insulation sheets and 100% of their surface after the installation and making sure that it is free of any of the very fine holes by using the most advanced testing equipment.

– Testing the welded joints at site and checking that they do not permit water to pass. Also testing their resistance to any other stresses which could be applied at site.

– Testing the defected parts after fixing it

4. The Geomembrane sheets can be installed on any concrete surface even if it has a complicated engineering shape. This is because of its durability and their ability to be formed for any shape.

5. The Geomembrane sheets can be installed on the wet concrete surface without the need to dry it by using special welding equipment which can perform well under bad conditions

6. A new Geomembrane sheets can be welded with an old one without any defects in the joint. The welded joints could be tested perfectly. This can help us to do the installation job on different steps or even we can carry out the installation of new sheets in the future if there is an expansion of work to the building.

The Geomembrane sheets can be used in the following applications:

• Foundation sealing.

• Bedrooms sealing.

• Roof sealing.

• Bathrooms sealing.

• Tunnels sealing.

• Concrete tanks sealing.

• Swimming pools sealing