Our Projects

Projects have been implemented in several fields, including high-density polyurethane (HDPE) system for lining treatment tanks and oil evaporation basins, waterproofing systems for surfaces exposed to rain water, epoxy flooring systems for industrial and service facilities and a polyurea system that exceeds the design parameters of engineering projects.

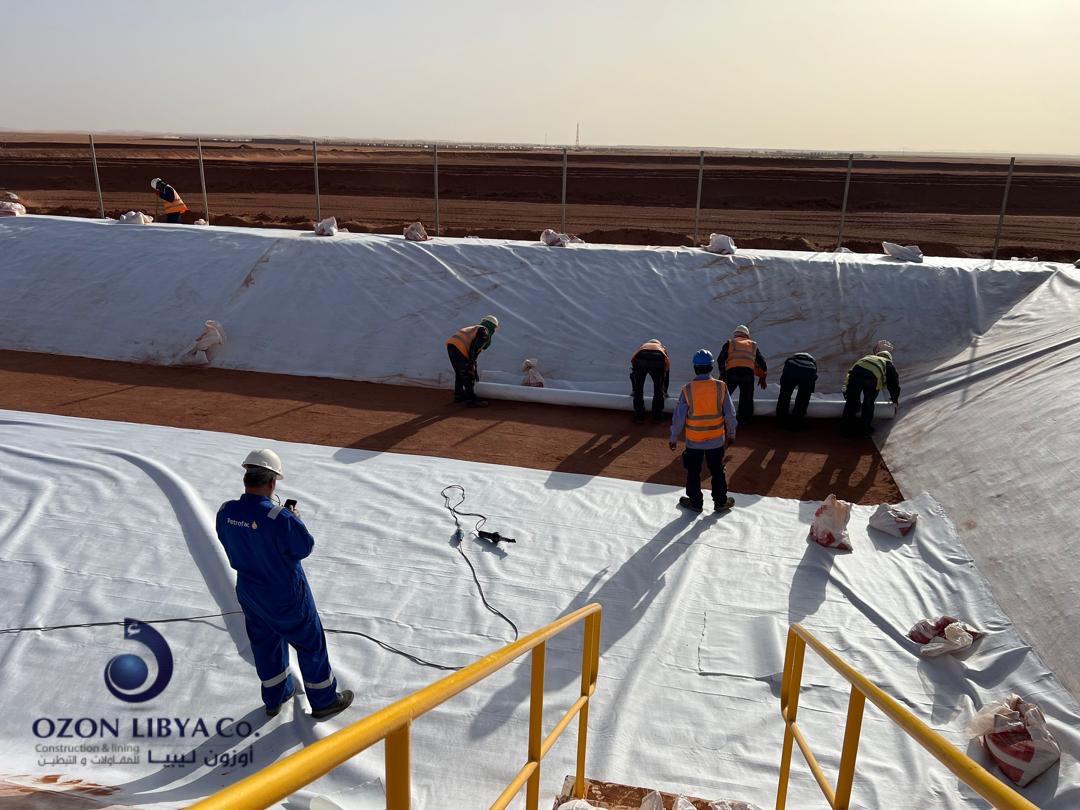

Lining of the chemical waste basin in the Mabrouk oil field

Owner: Al Mabrouk Oil Operations Company (Total)

Year of implementation: 2024

Metal Sections Pull Off Adhesion Test

Year of implementation: 2024

Part of the work of Ozone Libya Company in the field of tests to measure the cohesion strength of paint in metal sectors Pull Off Adhesion Test For Steel Structure

Project owner: Libyana Telecommunications and Technology Company.

Project contractor: ZTE Chinese Company.

Protection and insulation system for corridors and stairs floors at Tripoli International Stadium

Year of implementation: 2024

The project to protect and isolate the floors of corridors and stairs at Tripoli International Stadium was implemented with great success, despite the technical challenges and problems faced by the work team during implementation. Thanks to the fruitful cooperation between the Support Company for Contracting and Real Estate Investment and the supervising consulting team from Al-Banyan Office, in addition to the implementing team from Ozone Libya Company, accurate technical solutions were found for all challenges.

Insulation and lining of the evaporation basin of Zallaf Oil Production Company / 2

Year of implementation: 2024

Project owner: Antik Oil Services Company

Evaporation tanks are lined with 2.00 mm thick high density polyethylene (HDPE), in addition to lining with geotextile to enhance protection and flexibility. The latest equipment and devices are used in this project, all of which are calibrated to ensure the highest quality standards.

Insulation and lining of the evaporation basin of Zallaf Oil Production Company / 1

Year of implementation: 2024

Project owner: Zallaf Oil Company

Area: 15,000 square meters

A pioneering project in the field of lining evaporation tanks, where an innovative material was used for the first time in Libya. The project consists of lining a tank with an area of approximately 15,000 square meters using Conducive High Density Polyethylene with a thickness of 2.5 mm, which is a high-quality material that provides exceptional properties in terms of durability and flexibility.

Insulation of the roof of the Islamic Bank building

olive oil factory.

Area: 4200 square meters.

System type: Similis.

Epoxy is a chemical compound, one of the most severe types of chemical adhesives to floors, durable in terms of resistance to friction, and resistance to chemicals, whether acids, bases or solvents, as it forms as an insulating layer when dry, it is not capable of accumulating dust, water, dirt and microbes.

Year of implementation: 2020.

Execution time: 45 days.

Epoxy and primer European facility.

Coca-Cola Factory Epoxy Flooring

Epoxy is a chemical compound, one of the most powerful types of adhesive chemicals on floors and durable in terms of its resistance to friction, and resistant to chemicals, whether acids, bases or solvents, as it forms an insulating layer when it dries, as it is not susceptible to the accumulation of dust, water, dirt and microbes.

Evaporation Tank Lining And Insulation

Project owner: Al-Zawiya Oil Refinery.

Number of tanks: 1 tank.

Tanks dimensions 100m * 70m.

Quantity 7000 m2, thickness 1.5 mm.

The basin is completely insulated with high-density polyethylene, and the basins are used to separate oil and water, after which the oil is treated in order to preserve the environment.

Year of implementation: 2015.

Execution time: 20 days.

Evaporation Tank Lining And Iinsulation

Evaporation tank lining and insulation

Year of implementation: 2014

Project Contractor: Comet Oil Services Company

Number of tanks: 1 tank.

Tanks dimensions 120m * 120m

Quantity 16000 m2, thickness 1.5 mm.

The basin is completely insulated with high-density polyethylene, and the basins are used to separate oil and water, after which the oil is treated in order to preserve the environment.

Commercial Building Insulation

Project area: 550 square meters.

System: Acrylic system to protect the surface from water.

Implementation year: 2021.

Lining and Insulation Foundation of Building Investment

project owner : Investment Company The Purpose of the lining to protect and Preserve the foundation of the Building from corrosion and Extend the Life of the Building.

Implementation Date: 2014.

Period of Execution: 7 Days.

Ras Lanuf Lined Evaporation Ponds

project owner : Harouge Oil Operation.

Number of Tanks ( 2 ) Ponds.

Dimensins of Pond 120 m X 120 m.

Quantity of HDPE Sheet used 70,000m2 Thickness of Sheet 1.50mm.

purpose of Project is Preservation of The environment.

Implementation Date: 2010.

Period of Execution: 20 Days.

Lining And Insulation Of Earth Reservoir For Water Treatment

project owner : Implementation of Housing and utilities Projects Authority.

Dimensins of Reservoir 258 m x 121 m.

Quantity of HDPE Sheet used 46,500 m2.

Thickness of Sheet 1.50mm.

Water is used To Irrigate public gardens and parks.

Implementation Date: 2014.

Period of Execution: 30 Days.

Lining And Insulation Of Concrete Water Tank

project owner : Implementation of Housing and utilities Projects Authority.

Dimensins of Tank 110 m x 60 x 6 hight.

Quantity of HDPE Shet used 7000m2 Thickness of Sheet 1.00mm.

Water used for drinking.

Implementation Date: 2014.

Period of Execution: 20 Days.

Lining And Insulation Of earth Reservoir For Treated Water From Seweage Plant

project owner : ministry of Agriculture.

Number of Tanks ( 2 ).

Dimensins of Tank 160 m x 155 m.

Quantity of HDPE Sheet used 51,500 m2.

Thickness of Sheet 1.50mm.

Water Treatment used To Irrigate Agriculture project.

Implementation Date: 2013.

Period of Execution: 30 Days.

Lining And insulation Of Concrete Water Tanks

project owner : man-made river project.

Number of Tanks: ( 7 ).

Dimensins of Tank 220 m X 120 m 6 hight.

Size of Tank 90,000 Meter cube.

Quantity of HDPE sheet used 180,000 m2.

Thickness Of Sheet 1,00 mm.

Water is used to irrigate Farms.

Lining and Insulation Of Earth Reservoir For Water From Seweage Plant

project owner : Implementation of Housing and utilies Project s Authority.

Number of Tanks ( 2 ).

Dimensins of Tank 135 m X 595 m.

Quantity of HDPE Sheet used 105,000 m2.

Thickness of Sheet 1.50mm.

Implementation Date: 2010.

Period of Execution: 60 Days.

Lining And Insulation Of Concrete Water Tank (Project Abu Zayan – Rahibat)

project owner : man-made River Project.

Number of Tanks: ( 4 ).

Quantity of HDPE Sheet used 20,000m2 Thickness of Sheet: 1.00mm.

Water is used for lrrigatr Farms.

Implementation Date : 2009.

Period of Execution : 25 Days.